-

Mail Us @

admin@progassystems.com

-

Call Us On

+91-9820662450

Our service

Gas Handling Systems

A manifold is defined as a piping system fitted with several apertures for multiple connections used to transport gas from one location to another. A complete manifold system consists of cylinders, pigtails, end caps, extensions, starter blocks and the manifold control system.

In medical, industrial and laboratory environments there are two common situations where it becomes inconvenient to change over to a fresh gas supply. The first situation is one in which large volumes of gas are being used in relatively short periods of time thereby requiring the constant change over to a fresh gas supply. An equally frustrating situation arises when the same gas is being used in multiple locations (i.e. a large number of cylinders spread throughout various rooms). In either case, the requirement to frequently change cylinders becomes a major inconvenience. Gas Distribution systems are specifically designed to provide an economical method of gas system control by cutting down on the time required to replace the cylinders. This is accomplished by connecting several conveniently located cylinders or gas sources to a single manifold control system.

On site installation and commissioning services for Industrial, Medical and Speciality gas systems.

Tubing and Orbital Welding

PROGAS SYSTEM PVT LTD is a leader in orbital welding for tube and pipe. It also Implements proven orbital welding and fabrication techniques to meet the ever increasing demands of the Pharmaceutical, Semiconductor, Medical, Aerospace, Gas Industries and Instrumentation Industries.

Orbital welding is a specialized area of welding whereby the arc is rotated mechanically through 360° (180 degrees in double up welding) around a static workpiece, an object such as a pipe, in a continuous process. The process was developed to addresses the issue of operator error in gas tungsten arc welding processes (GTAW). Orbital welding is Automatic Tungsten inert gas welding. It eliminates chances of manual errors in welding. It is a computer-controlled process runs with little intervention from the operator. The process is used specifically for high quality repeatable welding. It produces identical welds for hundreds of times hence accuracy in welding.

• Equipment for Orbital Welding:

The main components of every orbital welding system are the power source and controller, the welding head and, where required, a wire feed mechanism. Welding of certain sizes and material types will also require the use of a water/coolant system. There are a large number of factors that can have an influence on the welding result. These aspects include the arc length, magnitude and pulse frequency of the welding current, welding speed, inert shielding gas, parent material, filler material, weld preparation, and thermal conductivity. Ultimately, a high quality weld is achieved through detailed knowledge of how to precisely adjust all these parameters for each individual welding task.

• Understanding the basic principles behind orbital tube welding may help you arrive more rapidly at the optimum weld procedure for your specific application.

• We provide orbital welding of tube upto 4” outer diameter performed by our qualified and certified workers.

• We also undertake turnkey orbital welding jobs as well as subcontracting jobs for orbital welding with supply of world class fittings and tubing / piping.

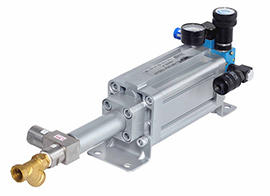

Hydro-static pressure testing pump

The efficient, economical alternative to centrifugal, vane, piston and plunger pumps and hand operated pumps.

At progas system pvt ltd we provide onsite hydro static pressure testing upto maximum pressure of 1000 kg/cm2 ( 14500 PSI)

Inhouse Test Bench

We have evolved designs for comprehensively testing Control Valves.

Covering a wide range of valve sizes and types, the systems are highly engineered to support the needs of both valve manufacturing businesses and service/repair workshops. They can be supplied with hydraulic or manual clamping mechanisms to suit any flange design as well as with adapters for threaded or other connections

PROGAS SYSTEMS has a wealth of experience and disciplines including hydraulic, pneumatic & plc / pc engineering to provide our customers with high quality, complex & reliable systems.

Pipeline installation

Introduction

Piping systems are the most commonly used method of conveying fluids in the gas and process industries. The integrity of piping systems is dependent on various considerations and principles that should be observed when designing, constructing and maintaining process plant piping. Pipework is made up of many components including pipes, flanges, supports, gaskets, bolts, valves, strainers, flexibles and expansion joints. Such components are available in a variety of materials, types and sizes and may be manufactured to a national standard or maybe a manufacturers proprietary item.

Design - Implementation of Pipework standards

Pipes and piping components are normally manufactured to meet the requirements of national standards such as ASME B31 Code for Pressure Piping or BS 1560 Circular Flanges for Pipes, Valves and Fittings.

We at progas system pvt ltd design and install pipe and control system for gases and liquids which includes:

+ Nitrogen

+ Argon

+ Oxygen

+ Hydrogen

+ Helium

+ Carbon Dioxide

We provide pipeline installation and services upto 300 Bar.

Pipeline Design Engineering

- Developing pipe routing and layouts as per ASME B 31.3

- Knowledge on plot plan, key plan, piping GA, piping isometric & final MTO

- Sizing of pipes and pressure drops.

- Preparation of Bill of Material (BOM).

- Generation of GA & Isometric drawings.

- Design and generate piping supports as per standards

TASK EXECUTED:

PIPING ENGINEERING & EXECUTION:

- Preparation of As-built drawings for pipe lines.

-Hydro testing of pipeline & station piping.

-Loop identification from P&ID and instrument loop diagram.

-Conducting Hydraulic test, compaction test, Radio graphic test.

-Confirm that the line is completed as per ISO drawing specifications.

-Installation of various pipes-carbon steel, stainless steel, cupro-nickel, Teflon, PVC.

-Checked and approved vendor drawings as per company procedures.

-Reviewing gauges calibration certificates prior to release for hydro test.

-Checking of piping specification class, valve datasheets & piping material selection.

-Entire piping inspection during site fabrication and shop fabrication.

-Hydro static pressure testing of pipe lines.

-Line list preparation.

-Witness PT, UT, MPT inspection.

-Making as built drawing for the lines.

-Inspecting material before erecting the line and initial stage of welding.

-Preparation of weekly and monthly reports to client and senior management.

-Handling the pre commissioning and flushing activities.

-Piping line check to confirm that the lines is completed as per ISO.

-Preparation, development and review of project quality plans.

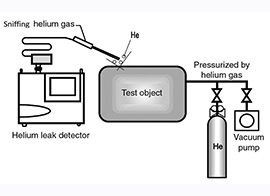

NDT Inspection - Helium Leak Testing

PROGAS SYSTEM offers a comprehensive NDT inspection service for both in-house manufactured items and onsite operations. We have fully trained NDT inspector to SNT-TC-1A 2001 - Level II, which enables us to write procedures, interpret results of inspections carried out and compile reports based upon any such findings. This NDT service can also be offered for hire to customers, with the inspector visiting the customer's premises or site.

Hose & Fitting supplies

We can supply both proprietary and customised hoses and fittings such as …

+ Swagelok fittings/ BALDOTA fittings

+ Vacuum hoses

+ VCR tube fittings

+ Stainless steel hoses

+ High pressure hoses & fittings

+ Hose connectors

+ Quick release coupling

Laboratory Installation

At PROGAS SYSTEM PVT LTD , you can depend on the purity and integrity of our products to help you conduct the most accurate experiments possible. We’ll supply your lab with a full line of high-purity analytical instrumentation gases, reagent gases, and gas mixtures, customized to your requirements. And we don’t stop there. Our laboratory services go far beyond gas supply. We offer a full line of cryopreservation and gas handling, distribution and storage equipment to help you work safely and productively.

We can provide a complete laboratory design and installation service which includes

+ High purity gas lines

+ Cylinder racks and storage cages

+ Gas chromatography lines

+ Flow & pressure controls

+ Fume extraction systems

Equipment and Laboratory Design- Clear communication, accuracy and quick turnaround are important to our clients. All aspects of laboratory design are handled by our professional team.

Fabrication Facility

Our In-house range of fabrication and welding facility includes..

+ Cylinder pallets/ cylinder cods

+ Cylinder trolleys

+ High pressure manifold systems

+ High pressure liquid and gas panel

+ Orbital welding

+ TIG welding for stainless steel and carbon steel

+ Light fabrication in steel, stainless steel, etc

+ Gas mixing & blending control panels